Plex Asset Performance Management

Machine health impacts every other plant floor KPI. With the Industrial Internet of Things (lloT), you can get a level of connectivity that can open the door to new opportunities to manage asset health while unlocking plant and business insights to enable data-driven decisions.

Plex Asset Performance Management (APM) allows you to do just that. Using IIoT technology, Plex APM offers today’s manufacturers a new way of networking machinery together to gain a much deeper understanding of efficiencies and of potential failures, before they happen.

Key capabilities: Turn insights into action

More and more manufacturers are discovering the value of adopting solutions that enable machine connectivity and facilitate monitoring of machine conditions and output without performing physical checks.

Plex APM optimizes the performance of machines, equipment, and other assets used in production and allows you to dive deeper into data and perform better across all manufacturing activities with:

- Connectivity to virtually any asset or data stream

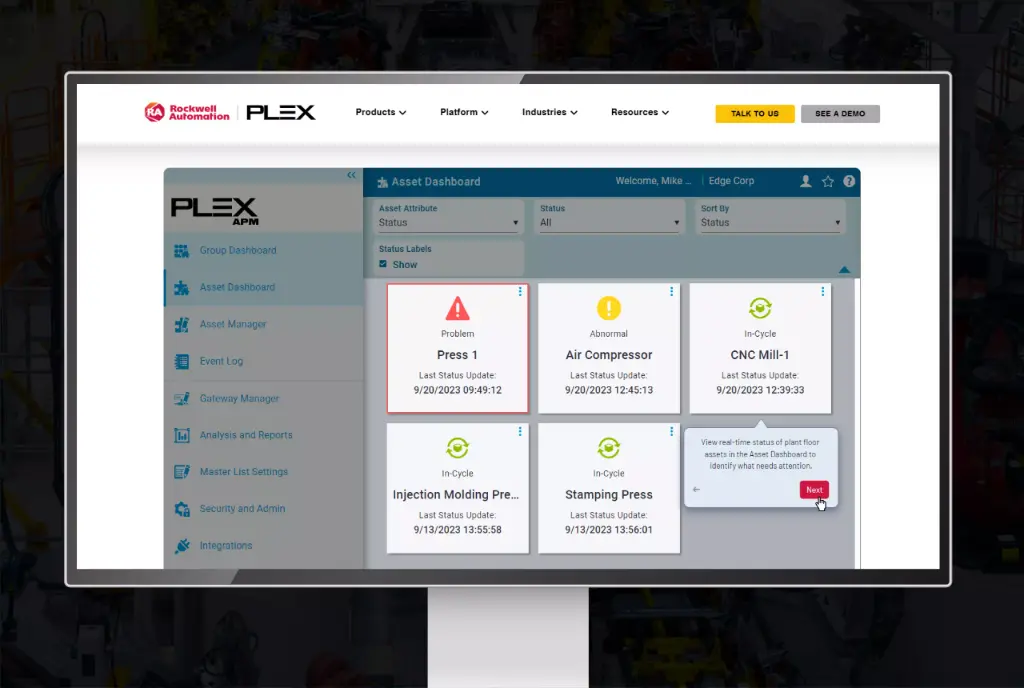

- Live dashboards of facility, work cell, or asset with easy-to-understand color coding

- Real-time views of asset status (Off, In-Cycle, Idle, Problem, Other)

- Remote access to dashboards anytime, anywhere, from any device

- Historical views of logged asset statuses and event logs

- Visualizations of data over time with graphical trend lines

- Multiple data streams from machines and sensors

- Security control to restrict access to authorized users

- Contextual data insights that combine process, operational, and machine data

What problems does Plex Asset Performance Management solve?

When your machines are not doing what they are supposed to be doing, it has a domino effect on every other aspect of your manufacturing success. If you’re experiencing any of the challenges below, your operation will benefit from the Plex APM application.

- Missed deadlines: Equipment failure and unplanned downtime lead to delays, missed deadlines, and plummeting customer satisfaction.

- Sub-standard products: With Plex APM, manufacturers can define required performance for their machines to make good product. Plex APM can notify team members quickly when it detects a machine performing outside of those thresholds so they can correct the issue quickly.

- Inability to rapidly respond to recalls: Product recalls are on the rise, yet many manufacturers still struggle to store and track the data necessary to react to recalls and protect their reputation.

- Inefficient micro-stops: Major production interruptions are often easy to identify and address, but micro-stops— short, yet frequent halts in production—often escape detection and create a noticeable drag on throughput and quality.

- Costly equipment repairs or replacement: Without real-time performance data, manufacturers often wait for machines to break down—or show significant signs of malfunction—before realizing it’s time to take them offline for maintenance. The result? Costly repairs and increased shipping and production costs to meet customer commitments.

30-day money-back guarantee

Shipping: 2-3 Business Days