Danfoss Ammonia Controls Application in Ice Production

During a recent refitting of an ice production plant, the application of Ammonia Controls from Danfoss led to a significant reduction in production down-time. It was noted that improvement was realized when compared to traditional procedures. Also, due to the advanced technology and their advanced features, installation was made much easier and faster. This led to substantial savings in installation costs, component costs, and loss of valuable production time.

Figure 1. Ammonia Refrigeration cycle in ice production.

The ice factory in Islamabad, Pakistan, was founded in 1972. Over the years, increased requirements for product quality and changing technical standards, as well as changes in market demand, mandated that they carry out a full technical automated re-equipment of their manufacturing plant with production capacity extension. (Fig 2)

Figure 2. The Factory.

The Challenge:

The main goal of shifting to ammonia controls and extension were to reduce energy consumption, to install modern and efficient equipment, to optimize temperature levels and to add the possibility of producing quality ice with a considerably less time and peace of mind.

The ammonia refrigeration plant with single-stage compressor units is supplied by circulation pumps. The brine which is cooled to about -5ºC by a refrigeration process extracts the heat from the water and produces block ice within the can. The cans are then removed from the tank and thawed for a short time in a tank of water to release the block from the can. The blocks are then stored in a cold room and can be crushed on demand (Fig 1).

Benefits of ammonia:

- GWP=0

- ODP=0

- High volumetric capacity

- Cheaper than HFCs/HCFCs

- Lowest total lifetime cost

- More effective than HFCs/HCFCs

- No phase out of ammonia so trust in the future of ammonia

- Downsized pipe dimensions etc.

These were the benefits their engineers sited for developing a solution caused to install ammonia controls. (Fig 3 & 4)

Figure 3.

Fig 4: shut-off valve / regulating valve / check valve / check & stop valve / strainer valves/ Sovs/Sensors etc. fitted on discharge and return lines of R-717.

Solution by Khan Brothers Islamabad:

As an authorized partner and expert of Danfoss in the area Khan Brother was the ultimate solution provider and have offered state of the art components for ammonia refrigeration and supplied a package of different valves etc. of Rs 3 million.

Khan Brothers turned them to Danfoss to combine quality components with expert knowhow and support. Tried out free tool of Coolselector® 2, designed, selected sizes and products to make work much easier.

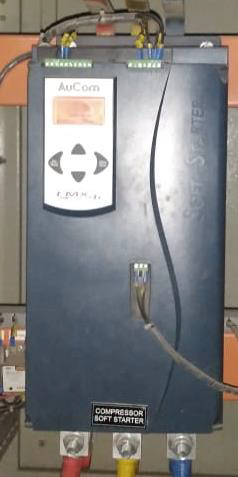

Fig 5: AuCom Soft starter, Compressor with Danfoss Pressure Switches.

Comments:

“The strong presence of Danfoss partner in the region, as well as a complete portfolio makes it possible to trust everything needed to a single provider, as well as the undisputed support of the brand globally”. (Factory Technical Team)