Project Completion Date: 27th January 2015

Introduction:

It was an obvious choice for HNR Co when it came to selecting a highly accurate and reliable machine for refrigerant charging, that Agramkow would be the right and only choice. HNR Co has had a wonderful experience since its inception by using EMAC-10 for R134a for their refrigerator line. HNR has also been using EMAC-25X machine on R22 for air conditioners.

System: (PROMAX)

The project entitled initially for R134a refrigerant with flexibility to convert to R600a for their refrigerator production for completion by Jan 2015. Agramkow provided guidelines regarding installation & Khan Brothers arranged commissioning & training of Agramkow’s PROMAX charging station for (R600a-flammable refrigerant) at HNR’s factory including following additional features.

SAFE EN Safe Emergency Notification (EN) System

Master and Slave units in charging area and supply areas respectively. The unique SAFE EN is a flexible and cost-effective safety control solution, which monitors and controls safety related functions in EX classified production area, repair areas and supply area.

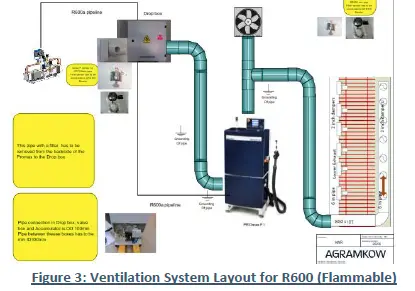

Drop box:

The drop box installation along with flow meters, gas sensors, alarm system, emergency stop & gas detectors in order to prevent flammable refrigerants to escape from drop box without notice. Furthermore, a possible leakage can be guided safely outside by means of a ventilation.

RS-F (flammable) pneumatic supply pump

RS-F (flammable) pneumatic supply pump integrated filter solution which is easy and cost-efficient as it is supplied by air only. Pump is “cooled” by air release during every pump stroke to maintain good chillier effect without need for cooling circuit.

Zone definition for Charging station, charging area, refrigerant storage area, Ex Zone 2, alarm Zone & fire free zone were being defined and labelled. More over flammable refrigerants supply lines were advised to colour code as well.

Automatic Disconnection (ADC) for operator’s easiness and to increase the process time as the process completes the gun automatically disconnects (ADC) from coupler.

Ventilation system: Importance of Ventilation and Exhaust fan is that in case of any emergency, SAFE EN System installed in charging station will run the exhaust fan at full speed and it will run continuously unless the concentration of Refrigerant in charging area reaches below 15%.In normal operation the exhaust fan runs at its nominal speed.

Installation & Commissioning: Promax Charging Station is installed and commissioned at HNR for R600a Charging and is working according to requirement. Ventilation ducts are installed to exhaust Refrigerant contaminated air by a Dual speed Exhaust Fan. Blow-off Unit is mounted in the repairing area to blow off Refrigerant. The system is running since January 2015, without any interruption. This has been done so satisfactorily and training imparted to HNR Co as well.

On Site Training: Khan Brothers (Lahore) assisted the whole project’s installation. Commissioning and training was done by Agramkow’s engineer Mr. Jacobsen, who not only commissioned the Project but also trained the operators, maintenance department & HNR engineers to better understand the functioning and monitoring of equipment.

Comments:

Mr. Muhammad Naeem (GM HNR) “Promises have been fully delivered by Khan Brothers and Agramkow’’

Mr Asif Nangiana (GM Ref /DF Factory at HNR) “Support from Khan Brothers has been very good, machine has been operating without issues since its initial setup in January 2014’’

Mr. Muhammad Ayaz (Manager QA at HNR) “Agramkow machine is very accurate in charge amount which is very important in R600a production”