Project Completion Date: 17th April 2015

Introduction:

DWP Group is a leading provider of products, service and solutions in the field of Consumer Electronics & Technology. Globally acclaimed, highly reliable products with cutting-edge technology from the world’s best engineered companies and experts uniquely position us to deliver comprehensive solutions to customers.

DWP Group is sole distributor and brand partner of Gree since 2005. DWP group has had a wonderful experience of using 2 machines of EMAC-25 for R22 at their Air conditioner line. Both EMAC 25 are working satisfactory at their factory since 2005 & 2006.

DWP’s reason for selection Agramkow was its precise & highly accurate repeatability of charge amount and local support available whenever required

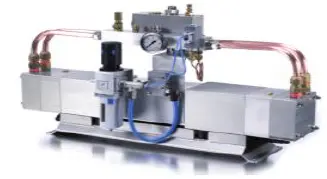

System: (EMAC-HS)

The project was called for R410a refrigerant for their air conditioner production. Agramkow provided guidelines regarding installation & Khan Brothers arranged commissioning & training of Agramkow’s EMAC-HS charging station for (R410a) at DWP’s factory

AGRAMKOW has engineered EMAC-HS (high speed) to improve productivity of a variety of evacuation and charging applications. It is easy to install and easy to use. It also has a versatile design to give you the flexibility to use it on different production lines, making it perfect for cell or low to medium volume production lines. And because it is durable and built to last, you can look forward to a long lifetime of low maintenance cost. EMAC carry out Evacuation, Vacuum check and Charging automatically. All common refrigerants R134a, R404A, R407C, R410A or R22 (others on request) are compatible with Emac HS.

Automatic Disconnection (ADC) for operator’s easiness and to increase the process time as the process completes the gun automatically disconnects (ADC) from coupler.

RS-170 Pneumatic supply pump integrated filter solution which is easy and cost-efficient as it is supplied by air only. Pump is “cooled” by air release during every pump stroke to maintain good chillier effect without need for cooling circuit.

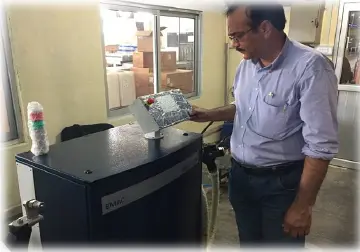

On Site Training: Khan Brothers (Lahore) assisted the whole project’s Commissioning while training was done by Khan Brothers assigned engineer, who not only assisted the Project but also trained the operators, maintenance department & DWP engineers to better understand the functioning and monitoring of equipment. Machine is working satisfactory since mid-April.

Comments:

Rizwan Rashid (GM Technical)

“We have been using Agramkow Gas Charging machines since 2005. We have found them to be highly accurate, reliable and user friendly in its operation. Khan Brother’s technical team has been providing us timely service and support whenever required”

Sher Dil (Senior Manager Production)

“I have been able to achieve production targets due to the steady and efficient performance of Agramkow Gas Charging Machines. These machines ensure precision and exact amount of refrigerant gas in the air conditioning units”

Fahad Younus (Manager Quality)

“Quality is very much assured with Agramkow Gas Charging machines. I have hardily seen any variation in the system performance even after many years of operation”