Year of Completion: 2018

Objective:

The objective of the projects to develop a failsafe system for diesel operation as under

• Automatic Operation of valves

• Automatic Diesel level monitoring and controlling system

• Pump Control System

• Filling of tanks both automatic and manual system

• Over Flow Protection

What we Did:

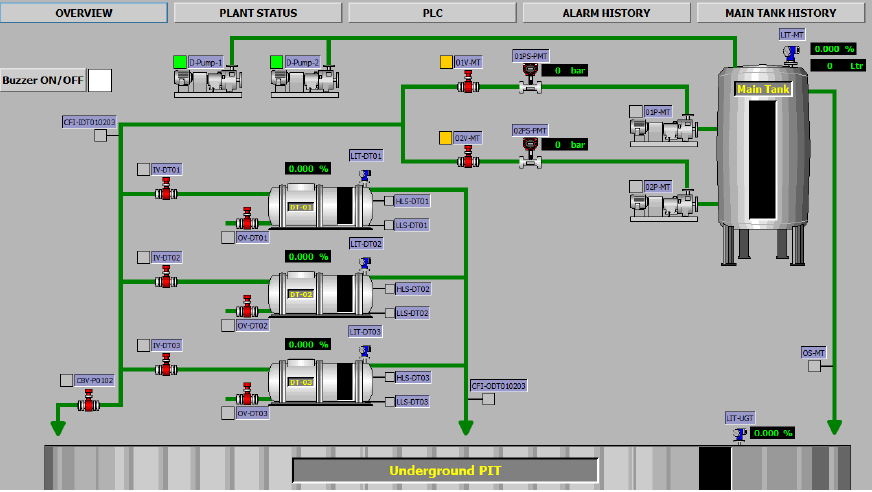

Siemens PLC has been used to integrate the whole process instruments with the system. Intended safety checks designed to avoid overflows & protections for valves .Sate of the art system intelligent enough to take automatic decision and in any case of failure send alerts to operator to take actions. Our database management system helps operator to control the plant in any emergency By Pass Assembly To operate the valve keeping better secure system By pass has been designed at the out let of tanks to avoid any failure in supply of diesel to generators.

PLC Control Design

Keeping international standards of wiring , ducting and control cabinet designed has been proper designed with all tags and details of wires for operator to easily access the system.

SIEMENS Continuous Level Monitoring

Using Siemens PROBE LUs we have develop a continuous monitoring system for a main tank and day tanks. With this instrument we are successfully able to monitor:

• Levels in tanks in Percentage

• Litters in the tank

• Accurate fuel consumption

Underground Tank Monitoring & Controlling using SIEMENS LUT430 To monitor the diesel in underground level tank we have used the state of the art LUT 400 series which has the ability to control the pump to remove the diesel from the underground tank

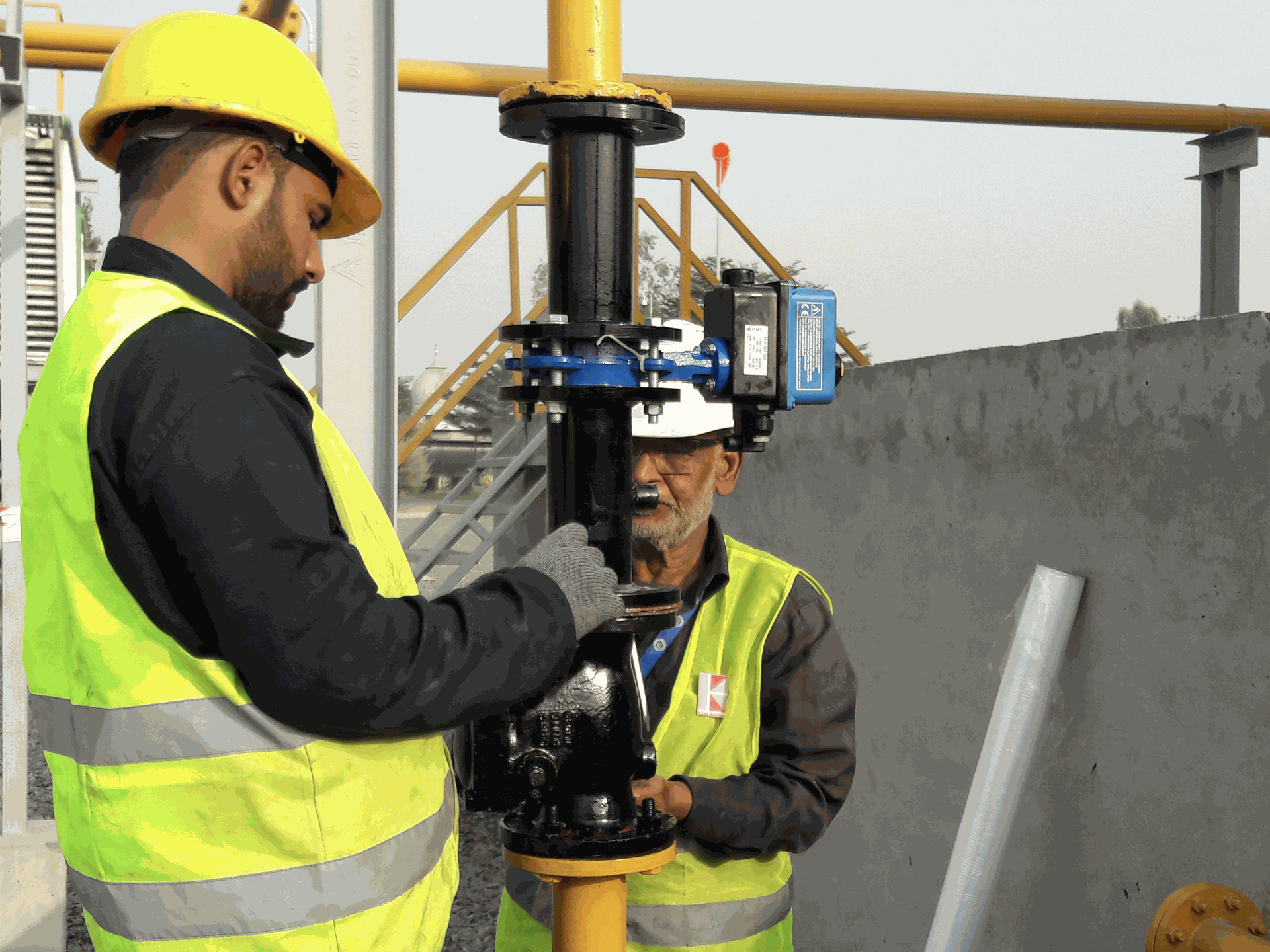

SOCLA Butterfly Valve

SOCLA valve has been to operate pumps based on the high & low level of day tanks.Highly standard valve with open and close indication at the HMI.

DANFOSS Solenoid Valves

At day tanks SOVs operated from control room with both manual and automatic mode options. System is user friendly and safety has been considered as our first priority.

By Pass Assembly

To operate the valve keeping better secure system By pass has been designed at the out let of tanks to avoid any failure in supply of diesel to generators.

Conclusion:

Automatic Level Monitoring: Siemens Level instrumet providing accurate reading in both percentage and litters to monitor exact flow and level in a day tanks

Automatic Control System: Filling of day tanks based on level point are controlled automatically from the control room. In automatic mode, the valves are open and close subjected to level in day tanks to fill the diesel. In manual mdoe the user just click on HMI to open and close the valve.

Safe & Secure System:

Develop a secure system to avoid overflow of diesel from the main and day tanks. System is integrated based on the reading from instrument and multiple check and alarm system provide alerts to operator.

Reliable System:

Accurate monitoring of diesel in tanks eliminated the paper work and user friendly system provides operator to control the system without moving into field.