Introduction:

Dawlance is one of the leading brands of home appliances, who made footprints in Pakistan way back in 1980. Later on, in 2016 it became subsidiary to Istanbul based Turkish company “Arcelik”. Where Globally they are working with 21 production facilities and 19 R&D/Design centers under 12 different brands. In Pakistan currently they are operational with three factories located in Karachi and Hyderabad, which are manufacturing freezers, split air conditioner, microwave ovens and washing machines.

REQUIREMENT: Environmental regulations remain serious concerns over the time in refrigeration industry as refrigerant contributes to ozone depletion as well as global warming. According to Clean Air Act of 2010, R-22 gas needs to be phase out until 2020 with Hydrochlorofluorocarbons (HCFC) R-410a and its complete ban on production and imports till 2030. UNIDO in this respect collaborate with Dawlance to upgrade their facility from R22/R410a to R290 for Air Conditioners (ACs), which is flammable but less effective to ozone depletion and global warming. The increasing use of the flammable refrigerant isobutane (R600a) in household appliances demonstrated that it is possible to safely use flammable refrigerants, thus opening the possibility to use R290 in other systems. Khan Brothers offered complete solution in collaboration with Agramkow, who had years of experience with fully automated system and dedicated team to provide complete support and services.

GLOBAL IMPACT OF REPLACING R22 WITH R290: The major impact on the producers will be the cost of equipment for leakage testing, charging, and safety installations in the factory. The energy efficiency and reliability of the appliance using R290 is expected to be equivalent to or better than that of equipment using R22. Because R290 has no ODP and a very low GWP, assuming that R290 has the same energy efficiency as R22, the environmental impact will be surely reduced. Based on estimated charge sizes and leak rates, emission savings are estimated to be 25 tons of R22 per 100,000 appliances.

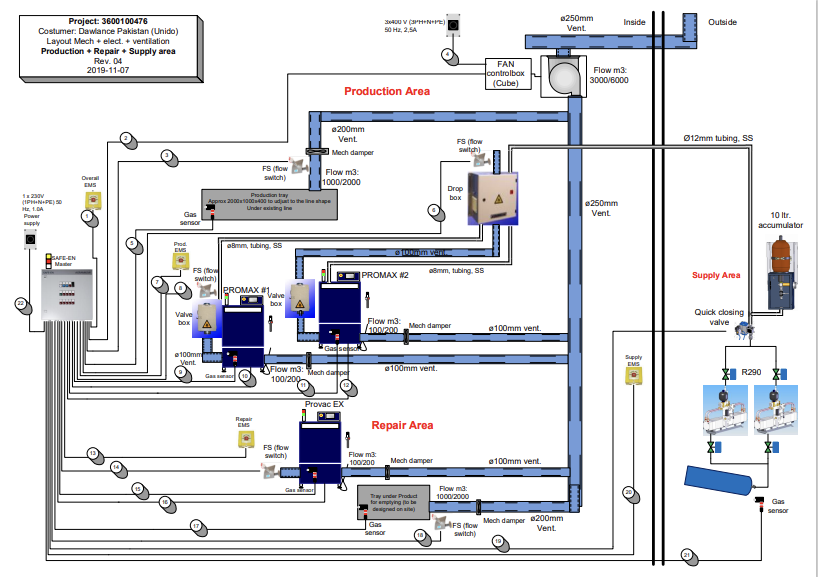

SYSTEM/EQUIPMENT: In order to upgrade Dawlance assembly line, Khan brother comes up with a complete solution for Charging R290 with PROMAX, Valve Box, Drop Box, Safe EN, Provac, Leak detector and ultrasonic welder. Same equipment is compatible for R32 refrigerant and R410 Refrigerant.

PROMAX: AGRAMKOW's FlexGun offers more charging critical features than any other gun in the market: DFC - Dynamic Flow Compensation for supply pressure drop ensures precision accuracy, and Gun heat for random charging performance improves accuracy and prevents condensation. Furthermore, the Automatic Disconnection (ADC) for pressure-less disconnection of R410A and hydrocarbons (R290 & R32) makes the clamp/unclamp process far more operator friendly and safe.

SAFE EN: With the SAFE-EN, AGRAMKOW was the first company to introduce a safety system that was designed in accordance with EN ISO 13849-1. This means that the SAFE-EN system is fully compliant with one of the strictest global standards for machine safety. It is also TÜV approved, which enables faster local approvals of installations.

INSTALLATION & COMMISSIONING: The project was installed under the supervision of Agramkow experts & Khan Brothers Engineers. Correct installation is a key factor that determines long-term product performance, enhanced operational life and minimize maintenance costs. We, Khan Brothers designed, developed, produced, assembled, and commissioned production line at DPL-2. In-depth consultation and project management together with our Principals & customer have always provided us a dominance over competitors.

TRAINING: AGRAMKOW work closely with industry partners and TÜV (Technischer Überwachungsverein - Technical Inspection Association) to assure the performance, reliability and safety of provided equipment for flammable refrigerants. The project is designed according to AGRAMKOW’s TÜV approved concept. This guaranties full ATEX compliance and ensures safe and reliable operation. As Dawlance evolves from synthetic refrigerants to natural propane (R290) in air conditioning, and training program to ensure that their operators, maintenance teams & Engineers know how to safely handle flammable refrigerants and related equipment so they can inform their peers.

CUSTOMER COMMENTS:

Mr. Tasawar Iqbal (factory manager)

"It is an excellent project experience with Khan Brothers and Agramkow teams, our people were well trained for operations and safeties to be considered while using Hydro Carbons & equipment."

Mr. Yamin Khan (Maintenance Manager)

"Good experience always rememberable for Dawlance management. Machines are running trouble free since being installed. Local technical support team of Khan Brothers is exceptional."

Mr. Asif Khan (Production Manager)

"A great working experience with Khan Brothers local team and Agramkow engineer, Agramkow equipment is reliable, accurate & precise. it was great learning exposure to advanced and updated technologies."